How Out-of-Stocks Affect Sales and What to Do About it?

Stockouts, or out-of-stock inventory, are a growing issue for brands and retailers. Imagine a loyal customer walks into a store or visits an online shop to purchase their favorite product, only to find it unavailable. Most customers won’t wait—they'll turn to a competitor, delay their purchase, or abandon their cart. Stockouts not only create immediate sales loss but also harm long-term customer loyalty and brand trust.

📉 Stockouts harm both your sales and brand image. Whether you’re selling grocery items, personal care products, or FMCG goods, stockouts have consequences that often go unnoticed until it's too late. The impact extends far beyond just lost revenue; it affects sales team tracking, customer retention, and market share. In this article, we’ll explore how stockouts harm your business and how efficient sales workflow enhancement can help prevent these issues.

📊 The True Cost of Stockouts: What the Data Shows

You might believe your stock availability is well-managed, but the actual data tells a different story. While larger brands report stockout rates of around 1.5% to 2%, real-world audits indicate that the true out-of-stock inventory levels can be as high as 8% to 10%, especially during sales promotions. Essentially, one in every ten purchases could be lost due to stockouts.

Prolonged stockouts are even more damaging. Although 75% of stockouts last less than 72 hours and account for only 14% of the total lost sales, the real damage happens when stockouts last more than 10 days. These long-lasting stockouts account for more than 50% of the total sales loss.

When stockouts persist, they don’t just result in immediate revenue loss—they provide competitors with an opportunity to take market share, weaken brand loyalty, and hurt retail partnerships. Addressing stockouts efficiently can help minimize these risks.

🔧 Why Stockouts Occur and How They Go Unnoticed?

Identifying the root causes of stockouts is crucial to preventing them. However, many businesses fail to detect the real reasons behind out-of-stock inventory problems. Research shows that 85% of stockout incidents—such as phantom inventory, delayed shipments, or poor stock replenishment—go unnoticed by field teams and brand managers.

Root cause analysis is key to resolving stockouts. Without a clear understanding of why stockouts are happening—whether due to faulty sales order management apps, poor inventory management, or supply chain disruptions—your business will continue to face recurring stockouts and missed opportunities.

📱 Manual Tracking isn’t Enough: Move to Data-Driven Solutions

Relying on field teams to manually track stock availability and inventory management can lead to missed opportunities and inefficiencies. Checking shelves, confirming replenishment orders, and manually verifying shipments are time-consuming and error-prone. This approach often fails to identify the most critical stockouts early enough.

Sales tracking apps are essential to streamline this process. In today’s fast-paced market, using manual tracking tools is inefficient and leaves your business vulnerable to stockouts. Automated systems, such as sales order management apps and sales route planning apps, monitor stock levels, predict replenishment needs, and send alerts to ensure issues are handled promptly.

💡 Automating Stockout Detection for Better Inventory Management

How can your business address stockouts and minimize their impact on sales? The solution lies in automation.

Automated stockout detection tools offer real-time visibility into stock availability across various stores and online channels. These tools track inventory movement, sales performance, and shelf visibility to quickly detect stockouts and send alerts to relevant teams. By automating this process, your business can resolve issues faster and prevent them from negatively impacting sales.

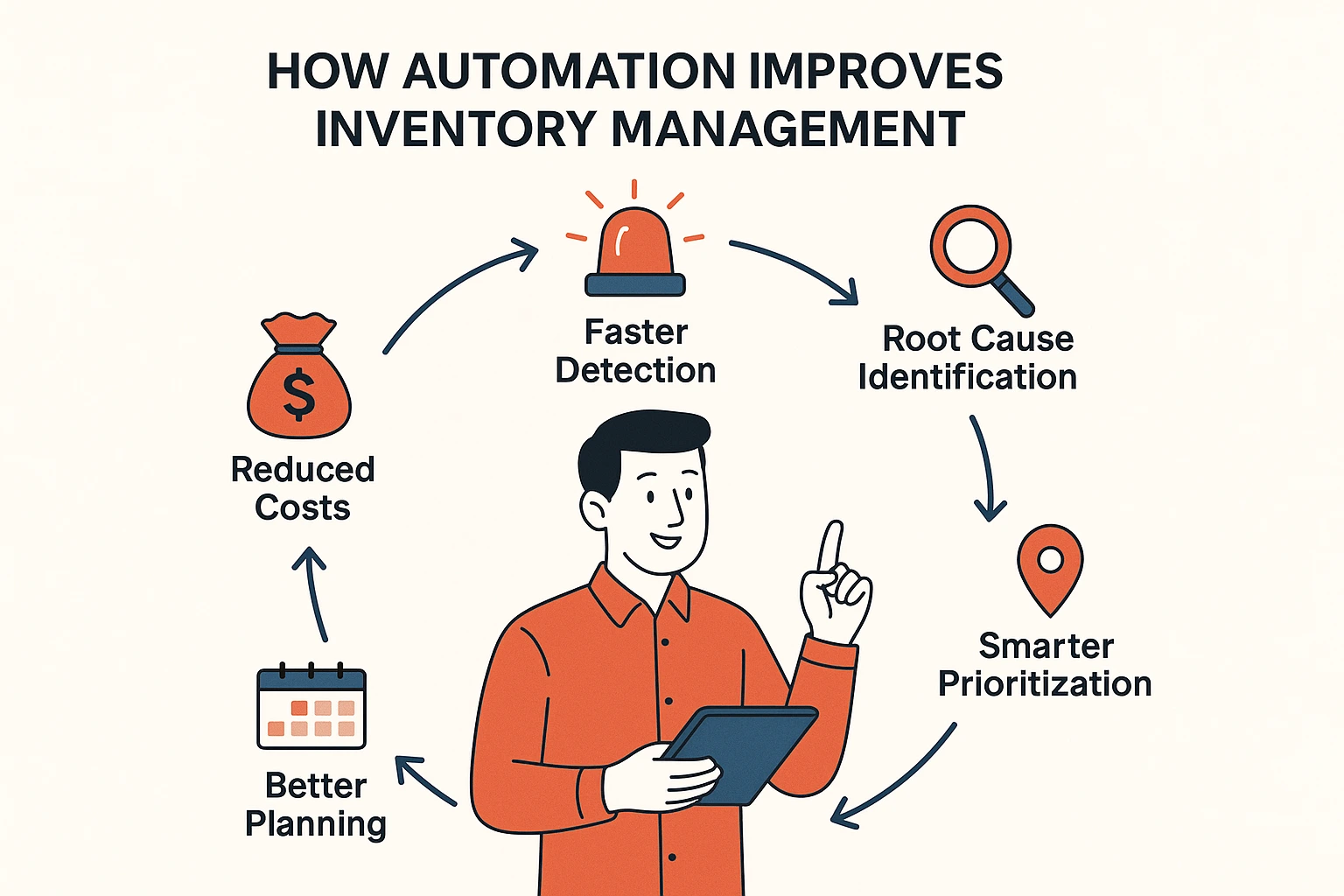

Here’s how automation can improve inventory management:

🚨 Faster Detection: Automated tools help detect stockouts quickly, reducing potential sales loss.

🔍 Root Cause Identification: Automated systems help identify whether stockouts are caused by poor inventory management, inaccurate stock tracking, or missed shipments.

📍 Smarter Prioritization: Focus on high-risk stores or products where stockouts will cause the most damage.

💰 Reduced Costs: Automation improves inventory management, reducing the costs associated with stockouts and improving profitability.

📅 Better Planning: Real-time data helps predict demand and adjust stock availability, reducing the chances of future stockouts.

By leveraging automated tools and improving inventory management, your business can stay proactive, reduce stockouts, and boost overall customer satisfaction and sales.

🔄 Improving Stock Availability for Better Customer Retention

In today's market, stock availability plays a crucial role in retaining customers. Even short-term stockouts can drive long-term revenue loss and harm customer loyalty. While some stockouts are inevitable, businesses that act quickly to restore stock availability will maintain customer trust and prevent significant losses.

Real-time stock availability tracking is key for ensuring your customers can always find the products they want. Whether you're using a field sales application, your brand remains competitive and resilient to stockouts.

🔍 FAQs on Stockouts and Automated Solutions

-

What causes stockouts?

Stockouts happen when products are unavailable due to supply chain issues, inventory management problems, or poor sales route management. -

How do stockouts impact customer behavior?

More than half of customers will switch to another brand or delay their purchase if their desired product is out of stock. -

What causes long-term stockouts?

Prolonged stockouts are often caused by poor inventory management, inaccurate forecasting, or delayed shipments. -

How can I detect stockouts faster?

Using automated tools such as sales force tracking apps and sales order management apps allows businesses to quickly detect and resolve stockouts. -

What’s the ROI of automating stockout detection?

Automation helps businesses reduce the frequency of stockouts, improve inventory management, increase sales, and enhance customer satisfaction.

Also Check

👉 Retail Execution Amid Labor Shortages: Empower Field Teams with Smart Sales Technology

👉 Effective Solutions to Manage Unsold Stock in FMCG

What Users Say About Us?

Our Delta Sales App has empowered teams across various industries to optimize field sales, enhance trade promotion management, and drive better store performance.

Want to see how it works in action? Check out users' feedback on the Delta Sales App!

⭐ Delta Sales App on Capterra