How to Keep CPG Products in Stock During High Demand

_1747634978.png)

Keeping Consumer Packaged Goods (CPG) products in stock during times of high demand is one of the biggest challenges for brands today. Supply chain disruptions, labor shortages, and sudden shifts in consumer buying patterns can quickly create out-of-stock situations. Poor stock management not only frustrates shoppers but also damages retailer relationships and reduces sales. That’s why CPG inventory management has become more critical than ever.

In this blog, we’ll explore four proven strategies that leverage retail execution, empower your field sales team, and improve on-shelf availability to ensure your products remain available when consumers want them most.

Boost Retail Execution Visibility for Smarter Stock Control

A top cause of stockouts is lack of timely data from the retail floor. Your field sales team is your eyes and ears in the store, but if they lack tools to report real-time inventory and display conditions, you’re flying blind.

By integrating mobile retail execution solutions, reps can capture on-the-spot information about stock levels, planogram compliance, and promotional setups. This data feeds into your inventory management system, enabling proactive replenishment before shelves run empty.

Benefits of enhanced retail execution visibility:

-

Quickly spot which SKUs are running low

-

Confirm planogram and promotional compliance

-

Empower reps to take corrective in-store actions immediately

Improving retail execution visibility is foundational to solid CPG inventory management—it reduces surprises and builds trust with retail partners.

Strengthen Demand Forecasting with Field Sales Insights

Traditional demand forecasting relying solely on historical sales misses critical on-the-ground signals. Incorporating data from your field sales team, such as shopper behaviors and shelf movement, creates a more accurate and agile forecast.

Adjust your inventory plans weekly using insights gathered through retail execution tools, factoring in upcoming promotions and local buying trends. This hybrid forecasting model helps you stock the right products, in the right quantities, at the right time—reducing both stockouts and excess inventory.

Tips for smarter demand forecasting:

-

Use retail execution data to refine forecasts regularly

-

Monitor regional trends impacting SKU demand

-

Include promotional calendars and shopper behavior insights

Effective forecasting is a pillar of efficient CPG inventory management, ensuring strong on-shelf availability during peak times.

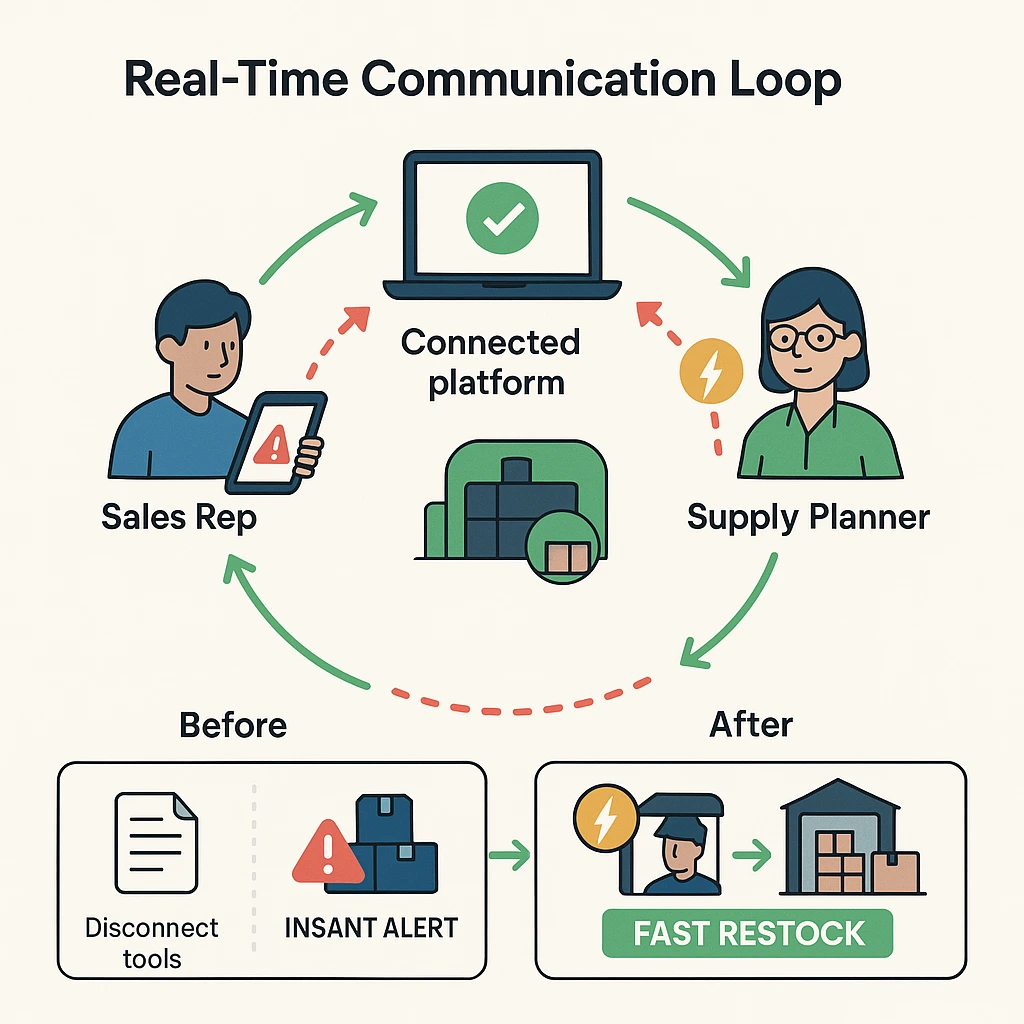

Streamline Cross-Team Communication for Faster Response

Stock issues often worsen due to delays in communication between sales reps, warehouse teams, and supply planners. Using disconnected tools or manual reports slows down the response to urgent restock needs.

By integrating your retail execution platform with inventory and logistics systems, all teams gain instant access to real-time stock updates. When a rep flags an out-of-stock, warehouse and supply chain teams can respond quickly before customers even notice.

Ways to enhance team collaboration:

-

Use centralized platforms for data sharing

-

Set automated alerts for low-stock or missed deliveries

-

Align teams with shared goals and KPIs

This seamless communication loop minimizes downtime and supports continuous on-shelf availability.

Empower Your Field Sales Team to Act Immediately

Your field sales team should be more than data collectors—they are problem solvers on the frontline. Equip them with the authority and tools to fix issues instantly from their mobile devices.

Whether it’s replenishing shelves from backstock, fixing displays, or escalating urgent requests with photos, these on-the-spot actions keep shelves full and customers satisfied.

On-the-spot solutions for reps include:

-

Requesting immediate restock

-

Rearranging shelf space to maximize visibility

-

Communicating urgent stock issues directly to HQ

Empowered reps dramatically improve your CPG inventory management outcomes and strengthen retailer trust.

Final Thoughts: Turning Stock Challenges into Competitive Advantage

In today’s fast-moving CPG landscape, CPG inventory management isn’t just logistics—it’s a key brand differentiator. Shoppers won’t wait if your product is missing; they’ll pick competitors instead.

By enhancing retail execution visibility, strengthening forecasting with field data, streamlining communication, and empowering your field sales team to act fast, you can significantly reduce out-of-stock occurrences. These strategies help your brand maintain consistent on-shelf availability, build retailer partnerships, and capture more sales—even during peak demand and unexpected disruptions.

Start implementing these proven tactics today and watch your CPG stock reliability and customer satisfaction soar.

📌 FAQs

1. What is CPG inventory management?

CPG inventory management refers to the processes and tools used by Consumer Packaged Goods companies to monitor, forecast, and optimize product stock levels across retail locations. Effective inventory management ensures the right products are available on shelves, reduces stockouts, and minimizes excess inventory.

2. How does retail execution impact inventory management?

Retail execution plays a critical role in CPG inventory management by providing real-time data on shelf availability, planogram compliance, and promotion performance. This visibility allows brands to take timely action to restock or adjust their in-store strategies, preventing lost sales.

3. Why is on-shelf availability important in CPG?

On-shelf availability is essential because if a product isn’t visible and accessible to customers, it can’t be sold. High on-shelf availability leads to better sales performance, improved shopper satisfaction, and stronger retailer relationships.

4. What tools can field sales teams use to improve stock visibility?

A field sales team can use mobile retail execution apps to capture in-store data, check stock levels, and report compliance issues. These tools improve accuracy in CPG inventory management and enable faster restocking decisions.

5. How can demand forecasting be improved in the CPG industry?

Demand forecasting in the CPG industry improves when companies combine historical sales data with real-time field insights. Using inputs from retail execution and the field sales team helps adjust forecasts more accurately to match consumer behavior and promotional impacts.

Explore More

👉 Perpetual Inventory Tracking: A Game Changer for CPG

👉 CPG Data Analytics: a Complete Guide to Smarter Sales

🗣️ What Users Are Saying About Us!

Delta Sales App, trusted by retail businesses for optimizing field productivity and streamlining sales processes, is highly rated on leading review platforms.

Discover how real users benefit from our technology:

⭐ Delta Sales App on Software Advice