Why Smart Inventory Management is Critical for Distributors Serving Manufacturers

Distributors sit at the heart of the supply chain, connecting manufacturers with retailers and end customers. Their role is vital, but managing inventory is often their biggest challenge. Stockouts, excess inventory, delayed deliveries, and inefficient warehouse operations are common problems that can severely impact profitability and relationships with manufacturers and retailers.

This is where smart inventory management becomes a game-changer. By integrating technology, automation, and analytics, distributors can not only maintain optimal stock levels but also drive efficiency, reduce costs, and strengthen manufacturer and retailer relationships. In a highly competitive marketplace, smart inventory management is no longer a “nice-to-have”; it’s essential. Leveraging modern technology and data-driven insights ensures distributors maintain accurate stock levels, optimize supply chains, and improve cash flow, while serving manufacturers efficiently.

In this blog, we will explore what smart inventory management is and why it is not just a tool but a strategic necessity for distributors in 2026 and beyond.

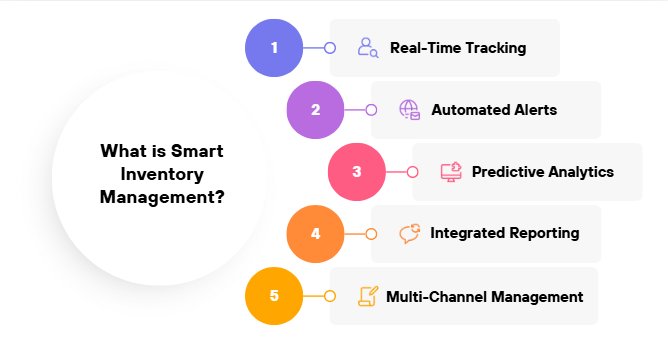

What is Smart Inventory Management?

Smart inventory management is the use of advanced technology, automation, and data-driven insights to monitor, track, and optimize stock. Unlike traditional inventory methods, which rely on manual counts and static spreadsheets, smart systems enable distributors to anticipate demand, reduce errors, and maintain optimal inventory levels.

Key features of smart inventory management include:

-

Real-Time Tracking

With real-time tracking, distributors can instantly monitor stock levels, product movement, and warehouse locations. Every inward and outward movement, whether goods are received, transferred, or dispatched, is recorded in the system immediately. When inventory data is delayed or inaccurate, stockouts and overstock become inevitable. Real-time tracking ensures distributors operate with complete and current information at all times.

-

Automated Alerts

Automated alerts serve as an early warning system for inventory-related issues. Smart inventory platforms alert distributors when stock levels fall below minimum thresholds, inventory exceeds optimal limits, or products are approaching expiration or shelf-life deadlines. These alerts reduce the need for manual checks and avoid costly mistakes like last-minute stock shortages or expired inventory losses.

-

Predictive Analytics

Predictive analytics forecasts future demand by using historical sales data, seasonal patterns, and market trends. Instead of relying on intuition or past habits, distributors can plan inventory using data insights.

-

Integrated Reporting

Integrated reporting uses dashboards and visual reports to transform raw inventory data into clear, actionable insights. Distributors can use these reports to analyze stock turnover rates, fast-moving vs slow-moving products, inventory aging and holding costs, and supplier and replenishment performance. Instead of managing multiple spreadsheets, decision-makers have a single source of truth for inventory performance.

-

Multi-Channel Management

Modern distributors frequently serve multiple channels simultaneously, including traditional retail stores, modern trade, e-commerce platforms, and direct B2B clients. Smart inventory management enables centralized visibility across all channels.

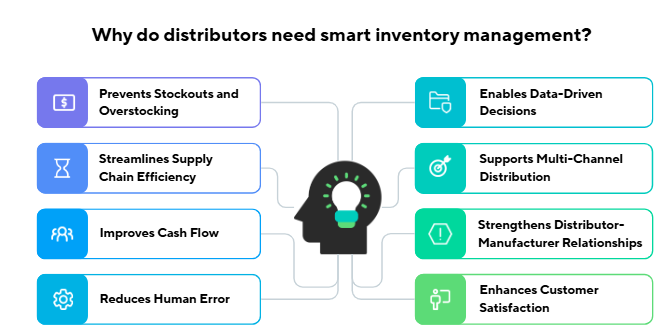

Why do distributors need smart inventory management?

Inventory is far more than products stored in a warehouse; it represents working capital, operational responsibility, and a critical driver of business performance. Distributors who rely on outdated or manual inventory processes often struggle with stockouts that result in lost revenue and dissatisfied customers, overstock that ties up cash flow and increases storage costs, inefficient supply chains that delay deliveries, and frequent errors caused by manual tracking and reporting. Smart inventory management addresses these challenges by providing real-time visibility, accuracy, and control, making it a critical foundation for efficient operations, stronger manufacturer relationships, and sustainable business growth.

Let’s break down the key reasons why smart inventory management is critical:

1. Prevents Stockouts and Overstocking

Distributors are constantly balancing having enough stock to meet demand and avoiding excess inventory. Poor inventory management leads to:

-

Stockouts

Stockouts occur when products are not available at the time of demand. For distributors, this means missed sales opportunities and immediate revenue loss. Frustrated retailers may switch to alternative suppliers. damaged relationships with manufacturers, because poor stock availability reflects inefficiency in distribution.

-

Overstocking

Overstocking occurs when excess inventory exceeds demand requirements. This leads to higher storage and warehousing costs, increased risk of product obsolescence or expiry, particularly in FMCG categories, and capital locked up in slow-moving stock, reducing liquidity for business growth.

Smart inventory systems address this by predicting demand based on historical data, current trends, and market insights. For example, a beverage distributor that serves multiple supermarkets experienced frequent stockouts during the holiday season. Stockouts were reduced by 40% after implementing smart inventory tracking, resulting in increased sales and retailer trust.

2. Streamlines Supply Chain Efficiency

Inventory management is at the heart of a well-run supply chain. When distributors implement smart inventory systems, the flow of goods from warehouse storage to final delivery becomes faster. more reliable, and cost-effective. A 2025 survey revealed distributors using integrated inventory management solutions reduced delivery delays by 30% and operational bottlenecks by 25%.

Each part of the supply chain benefits in the following ways:

-

Fulfill orders faster

Smart inventory systems enable real-time visibility into available stock, eliminating the need for manual checks and confirmation delays. Orders can be processed immediately because distributors know exactly what is available and where it is located. Automated picking lists and inventory updates further reduce processing time, allowing retailers and manufacturers to fulfill orders more quickly and provide better service.

-

Optimize logistics and transportation

Accurate inventory data enables distributors to plan deliveries more effectively. Knowing exact stock quantities and warehouse locations is useful for optimizing vehicle loads, planning delivery routes, and scheduling shipments. This reduces unnecessary trips, lowers fuel costs, and ensures on-time deliveries, thereby improving overall logistics performance.

-

Reduce warehouse bottlenecks

Poor stock organization and manual handling are common causes of warehouse bottlenecks. Smart inventory management systems simplify warehouse operations by guiding the picking, packing, and stock placement processes. This minimizes congestion, reduces idle time, and improves workflow efficiency, ensuring that goods move smoothly within the warehouse.

-

Provide manufacturers with accurate stock data

Manufacturers rely on distributors for accurate and timely inventory information when planning production and replenishment. Smart inventory systems allow distributors to share real-time stock levels, sales trends, and movement information. This transparency improves coordination, reduces supply mismatches, and strengthens distributor-manufacturer relationships.

3. Improves Cash Flow

Inventory represents money tied up in products. Overstocking limits the distributor’s ability to invest in growth, while stockouts reduce revenue. Smart inventory management enables:

-

Minimization of idle stock

Idle or slow-moving inventory wastes capital and generates no returns. Smart inventory systems detect products with low turnover and aging stock, allowing distributors to adjust procurement, run targeted promotions, and rebalance inventory. By reducing idle stock, distributors free up cash that would otherwise be locked in unsold products.

-

Capital allocation to high-demand products

With clear visibility into sales trends and product performance, distributors can prioritize investment in high-margin, fast-moving products. Smart inventory management directs capital toward SKUs that generate consistent demand and revenue, maximizing return on investment while minimizing waste on underperforming items.

-

Optimized procurement and replenishment

Instead of relying on estimates or fixed schedules, smart systems align procurement cycles with actual demand. Automated replenishment recommendations assist distributors in purchasing inventory at the appropriate times and quantities. This prevents over-purchasing, lowers emergency purchasing costs, and maintains cash flow throughout the supply chain.

4. Reduces Human Error

Manual inventory management is heavily reliant on human input, making it prone to errors like miscounted stock, misplaced products, delayed updates, and inaccurate reporting. Even minor errors can cause ripple effects throughout the supply chain, resulting in incorrect orders, delivery delays, and disputes with retailers or manufacturers.

Smart inventory management systems significantly reduce these risks by automating stock counting, tracking product movement in real time, and producing accurate system-generated reports. Every inventory action ; receiving, transferring, picking, or dispatching, is instantly recorded, eliminating guesswork and reducing the need for manual data entry.

Automation not only increases accuracy, but it also ensures consistency and accountability among warehouse and distribution teams. With accurate inventory data, distributors can confidently fulfill orders, reduce returns, and maintain transparency with manufacturers.

For example, an FMCG distributor implemented handheld scanners and mobile inventory applications throughout its warehouses. As a result, inventory-related errors decreased by 35%, order fulfillment accuracy increased significantly, and disputes with manufacturers over stock discrepancies were greatly reduced.

5. Enables Data-Driven Decisions

In today's fast-paced markets, distributors cannot rely on assumptions or past habits to manage inventory. Smart inventory management systems provide distributors with real-time, data-driven insights that enable faster and more accurate decision-making across all operations. Smart inventory systems offer the following:

-

Product performance trends

Smart inventory management systems monitor sales velocity, stock turnover, and movement patterns for each SKU. This enables distributors to easily identify fast-moving, slow-moving, and underperforming products. With this visibility, businesses can concentrate on high-performing items while decreasing investment in products that do not contribute to profitability.

-

Seasonal demand predictions

Smart inventory systems assist distributors by analyzing historical sales data and seasonal trends to predict demand fluctuations. Whether it's the holiday season, a promotional period, or weather-related demand, distributors can plan ahead of time to avoid stockouts and excess inventory.

-

Supplier reliability metrics

Inventory analytics also provide information about supplier performance, such as delivery timelines, order accuracy, and replenishment consistency. Distributors can use this data to work more closely with reliable suppliers, renegotiate terms, or address recurring supply issues proactively.

This helps distributors decide which products to stock, which SKUs to phase out, and how to optimize warehouse layouts. Example: A cosmetics distributor quickly restocked a trending product using analytics insights, avoiding lost sales and outperforming competitors.

6. Supports Multi-Channel Distribution

Today’s distributors rarely operate through a single sales channel. Most cater to a mix of traditional retail outlets, modern trade, e-commerce platforms, and direct B2B customers. Managing inventory across these channels without a smart system frequently results in stock conflicts, overselling, and missed opportunities. Smart inventory management addresses this issue by ensuring consistent control and visibility across all channels. Smart inventory management ensures that:

-

Real-time stock visibility across channels

Smart inventory systems provide a single, centralized view of inventory that is updated in real time across all sales channels. Stock levels are adjusted instantly when a product is sold online, via a field sales order, or at a retail outlet. This avoids discrepancies, double-selling, and confusion among teams.

-

Coordinated replenishment and delivery

With accurate, real-time inventory data, distributors can better plan replenishment and delivery across channels. Smart systems assist in prioritizing orders based on demand, channel importance, or delivery timelines, ensuring seamless coordination and timely fulfillment without disrupting other channels.

-

Accurate reporting for manufacturers

Manufacturers rely on distributors for clear information about product movement across channels. Smart inventory management provides channel-specific sales and stock reports, allowing manufacturers to better understand demand patterns and plan production accordingly. This transparency promotes collaboration and long-term partnerships.

7. Strengthens Distributor-Manufacturer Relationships

"Trust is built when promises are consistently kept." In the same way, distributors and manufacturers can develop strong, long-term relationships when distributors consistently maintain product availability, provide accurate demand forecasts, and share real-time inventory data. Distributors demonstrate reliability and transparency by ensuring stock availability when needed, aligning replenishment with actual market demand, and avoiding production misalignments, allowing manufacturers to plan production efficiently, reduce operational risks, and boost confidence in their supply chain partners. Manufacturers rely on distributors to:

-

Maintain product availability

Manufacturers expect distributors to ensure that their products are consistently available on the market. Smart inventory systems enable distributors to monitor stock levels in real time, anticipate demand spikes, and replenish items quickly. By preventing stockouts, distributors assist manufacturers in maintaining market presence, increasing sales, and protecting their brand reputation.

-

Provide accurate forecasts

Distributors who use smart inventory management can create data-driven demand forecasts based on past sales, seasonal trends, and market insights. These forecasts enable manufacturers to plan production schedules, raw material procurement, and capacity utilization more efficiently, reducing waste and avoiding under- or overproduction.

-

Avoid production misalignments

Inaccurate or delayed inventory information can result in production mismatches, such as producing more products than necessary or failing to meet market demand. By sharing precise, real-time inventory data, distributors enable manufacturers to closely align production with actual market demands, reducing operational inefficiencies and costs.

8. Enhances Customer Satisfaction

Smart inventory management directly improves customer experience. Accurate stock levels, timely deliveries, and reduced errors lead to:

-

Higher retailer satisfaction

Distributors can ensure product availability by using real-time inventory visibility. Retailers can rely on consistent stock levels to meet consumer demand, which builds trust and strengthens business relationships.

-

Fewer complaints

Automated tracking, alerts, and accurate reporting reduce errors like delayed deliveries, incorrect shipments, and stock discrepancies. Fewer errors result in smoother transactions and fewer disputes with retailers, which improves efficiency and reputation.

-

Increased repeat orders

Consistently reliable service encourages retailers to place repeat orders, resulting in long-term business relationships. Repeat orders increase revenue and give distributors a competitive advantage in the market.

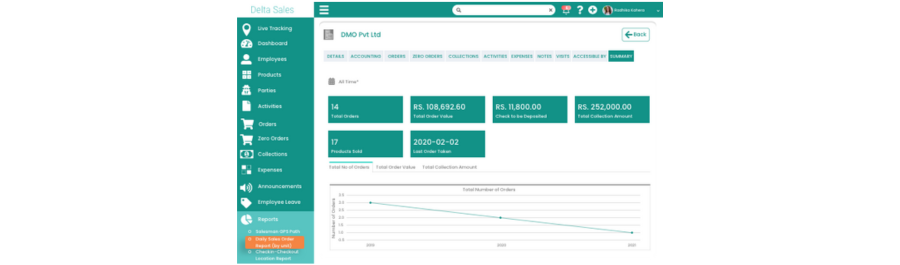

DeltaSales App: The Smart Solution for Distributors

While the benefits of smart inventory management are obvious, successfully implementing them necessitates the right technology platform. DeltaSales App is tailored specifically for distributors, offering a comprehensive, all-in-one solution that streamlines inventory, improves accuracy, and boosts supply chain performance.

The Delta Sales app provides a comprehensive solution designed for distributors:

-

Real-Time Inventory Tracking

The DeltaSales App allows distributors to instantly monitor stock levels in warehouses, retail stores, and field locations. This real-time visibility ensures that products are always available when needed, reduces stockouts, and helps to maintain optimal inventory levels.

-

Automated Alerts

The app sends timely notifications for low stock, overstock, and expiration dates, allowing distributors to take immediate action. This proactive approach prevents lost sales, minimizes waste, and ensures inventory is always in line with demand.

-

Integrated Reporting & Analytics

The DeltaSales App offers visual dashboards, reports, and actionable insights to help distributors forecast demand, analyze product performance, and optimize procurement. These analytics enable data-driven decision-making, allowing distributors to cut costs and increase profits.

-

Seamless Multi-Channel Management

The app allows distributors to manage inventory across multiple channels, including retail stores, e-commerce platforms, and B2B clients. Accurate, centralized data ensures smooth fulfillment, prevents overselling, and effectively balances stock across all channels.

-

Mobile Access

Using mobile devices, field staff can update stock in real time, scan products, and track deliveries, reducing manual errors and increasing operational efficiency Mobile access also connects distributed teams, ensuring timely and accurate reporting from anywhere.

Example: A distributor using the DeltaSales app optimized warehouse stock, reduced overstock by 30%, improved retailer delivery efficiency, and strengthened manufacturer trust, all within six months.

Why DeltaSales Stands Out:

-

User-friendly interface for teams at all levels

-

Cloud-based system with secure access

-

Integration with existing ERP or CRM systems

-

Support for analytics-driven decision-making

Conclusion

"Efficiency is doing things right; effectiveness is doing the right things." — Peter Drucker. In distribution, efficiency ensures that operations run smoothly, while effectiveness guarantees that the right inventory decisions are made to meet market demand. Smart inventory management enables distributors to achieve both preventing stockouts and overstock, streamlining supply chains, increasing cash flow, reducing human error, and allowing for data-driven decisions. It also improves relationships with manufacturers and increases retailer satisfaction, transforming inventory into a strategic asset rather than a cost center.

DeltaSales App offers a comprehensive, all-in-one solution that includes real-time inventory tracking, automated alerts, analytics, multi-channel management, and mobile accessibility. Start optimizing your operations, gain real-time insights, and strengthen your relationships with manufacturers and retailers, all from a single, easy-to-use platform.

Get started with Delta Sales App Today and experience smarter distribution!